Factory 220V CNC Lathe Machine 0.2kw 0.64 1.91N.m 3000 5000 rpm 60mm AC Servo Motor

As one of the servo motors manufacturers, suppliers, and exporters of mechanical products, We offer servo motors and many other products.

Please get in touch with us for details.

Mail:[email protected]

Factory 220V CNC Lathe Machine 0.2kw 0.64 1.91N.m 3000 5000 rpm 60mm AC Servo Motor

Introduction

The Factory 220V CNC Lathe Machine is equipped with a 0.2kw 0.64 1.91N.m 3000 5000 rpm 60mm AC Servo Motor. This motor is an essential component of the lathe machine, providing precise control and efficient operation.

Function and Features

The AC Servo Motor plays a crucial role in the operation of the CNC Lathe Machine. Its main functions and features include:

- High Precision Control: The motor ensures accurate and precise positioning for enhanced performance.

- Quick Response: It offers fast response times, allowing for efficient and dynamic operation.

- High Torque Density: The servo motor delivers high torque output in a compact design.

- Wide Operating Range: It can operate within a broad range of speeds and torques, making it versatile for various applications.

- Improved System Efficiency: The motor enhances overall system efficiency, reducing energy consumption.

- Enhanced Production Quality: With its reliable and precise operation, it contributes to improved product quality.

Working Principle

The AC Servo Motor works based on feedback control. It consists of several key components:

- Controller: The controller processes the control signals and provides instructions to the motor.

- Driver: The driver amplifies the control signals and delivers the necessary power to the motor.

- Motor Body: The motor body consists of coils and magnets that generate the rotational force.

- Feedback Device: The feedback device, such as an encoder, provides position and velocity feedback to the controller.

These components work together to achieve precise position, velocity, and acceleration control.

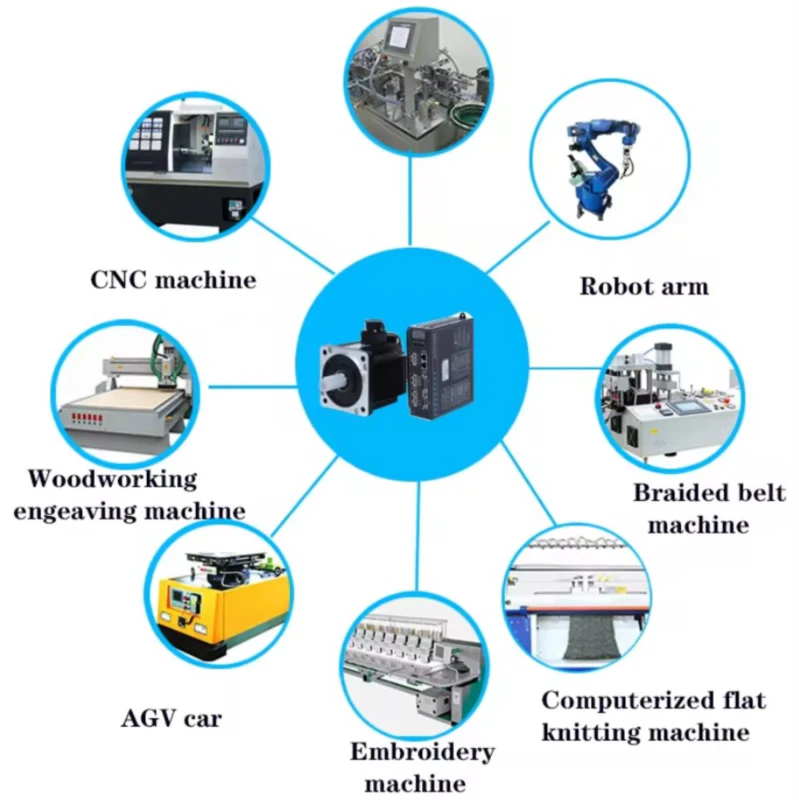

Applications

The AC Servo Motor finds extensive applications in various industries, including:

- Manufacturing: It is widely used in CNC machines, robotics, and automated production lines.

- Automation: Servo motors are essential for precise control in automated systems and industrial processes.

- Medical Equipment: They are utilized in medical devices, such as imaging systems and surgical robots.

- Aerospace: The motors are employed in aerospace applications, including aircraft control systems.

Advantages and Types

There are several types of servo motors, each with its advantages and disadvantages:

- AC Servo Motors: These motors offer high torque and speed capabilities, suitable for demanding applications.

- DC Servo Motors: They provide precise control and are commonly used in industrial automation.

- Brushless Servo Motors: These motors offer long lifespan and low maintenance requirements.

The choice of servo motor depends on the specific requirements of the application, considering factors such as speed, torque, and control precision.

Company Introduction

Our company is a leading player in the Chinese motor market. We specialize in the design and production of various motors, including servo motors, brake motors, Hydraulic Motors, Bauer gear motors, hydraulic pistons, and driveline motors. With a production capacity of 200,000 sets, we utilize state-of-the-art automatic CNC production and assembly equipment.

We take pride in offering high-quality products, competitive prices, and excellent customer service. We welcome customers to customize their orders based on drawings and samples.

Factory Image

Related Products

-

2KW 7.7N.M High precision IP65 AC servo motor with encoder, Servo Motor and Driver

-

CNC servo 2.4KW 15.2N.M 3000RPM servomotors high torque servo motor with drive kit

-

Energy Saving 1000W Servo Motor Kit 1KW 3.2Nm 5000RPM Modbus485 CANOpen EtherCat Servo Motor and Drive with Oil Seal and Brake

-

Factory 220V CNC Lathe Machine 0.2kw 0.64 1.91N.m 3000 5000 rpm 60mm AC Servo Motor