Servo motors for scalability in modular manufacturing setups

Introduction

Servo motors play a crucial role in ensuring scalability and efficiency in modular manufacturing setups. Their precision, versatility, and ability to adapt to various industrial applications make them essential components for modern production lines. This article explores the benefits of servo motors and their importance in achieving optimal performance in modular manufacturing environments.

1. Understanding Servo Motors

Servo motors are highly efficient electromechanical devices that convert electrical energy into precise rotational motion. They consist of a rotor, stator, and feedback control system, which work together to accurately position or control the speed of machinery. With their ability to provide precise motion control, servo motors offer numerous advantages in modular manufacturing setups.

2. Advantages of Servo Motors

Servo motors provide several benefits that contribute to the scalability and efficiency of modular manufacturing setups:

- High Precision: Servo motors offer exceptional accuracy, enabling precise positioning and control of machinery within the manufacturing process.

- Fast Response Time: These motors have rapid acceleration and deceleration capabilities, facilitating quick changes in production speed or direction.

- Flexibility: Servo motors can be easily programmed and adjusted to meet specific manufacturing requirements, making them suitable for a wide range of applications.

- Energy Efficiency: By operating at optimal speeds and consuming only the necessary power, servo motors contribute to energy savings and cost reduction.

- Reliability: With their robust design and advanced feedback control systems, servo motors offer long-term reliability and durability in industrial environments.

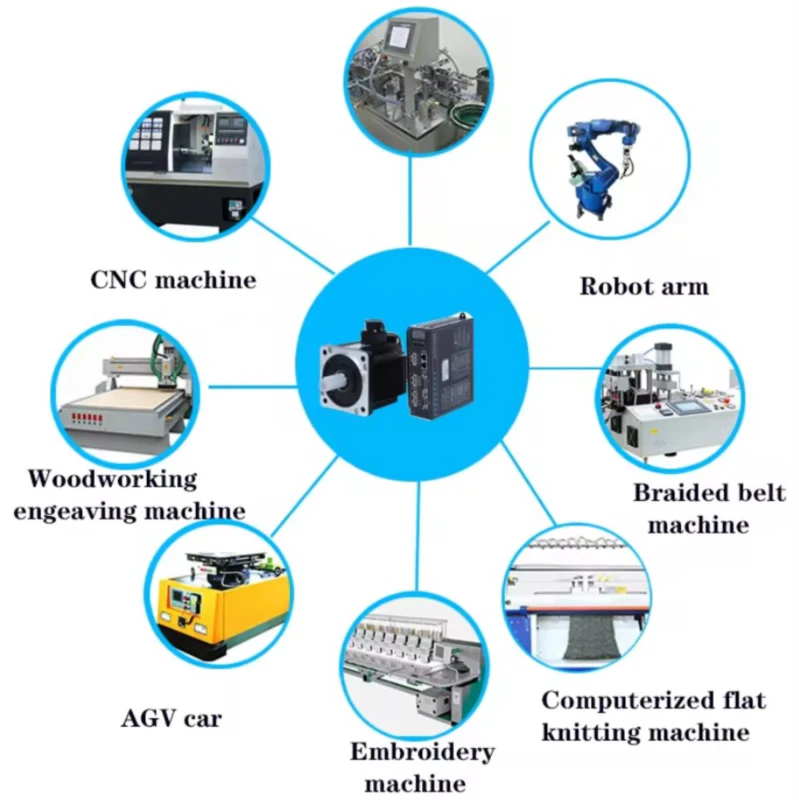

3. Applications of Servo Motors in Modular Manufacturing

Servo motors find extensive use in various applications within modular manufacturing setups:

- Robotic Assembly: Servo motors enable precise movements and coordination in robotic arms, improving the accuracy and efficiency of assembly processes.

- Packaging and Labeling: These motors ensure accurate positioning and synchronization for packaging and labeling machines, enhancing production speed and quality.

- Motion Control Systems: Servo motors provide the necessary motion control for conveyors, indexing tables, and other equipment, optimizing material handling and production flow.

- CNC Machining: Servo motors drive the axes of CNC machines, enabling high-precision cutting, drilling, and milling operations.

- Automated Testing: Servo motors facilitate precise movements and control in testing equipment, ensuring accurate and repeatable test results.

4. Q&A

Q: Why are servo motors preferred over other motor types in modular manufacturing setups?

A: Servo motors offer superior precision and control, allowing for accurate positioning and synchronization of machinery, which is crucial in modular manufacturing setups where flexibility and efficiency are paramount.

Q: How do servo motors contribute to scalability in modular manufacturing environments?

A: By providing precise motion control and adaptability to various applications, servo motors enable manufacturers to easily scale up or modify their production processes to accommodate changing demands or product variations.

Q: Can servo motors reduce production costs in modular manufacturing setups?

A: Yes, servo motors contribute to cost reduction by optimizing energy consumption, improving production efficiency, and minimizing errors or waste through precise control and positioning.

Conclusion

In conclusion, servo motors play a vital role in achieving scalability and optimal performance in modular manufacturing setups. Their precision, flexibility, and reliability make them indispensable components for various industrial applications. As a leading company in the Chinese motor market, we specialize in providing high-quality servo motors, brake motors, hydraulic motors, Bauer gear motors, and more. With our design and production capacity of 200,000 sets, we offer exceptional products at competitive prices, coupled with excellent customer service. We welcome customization requests based on specifications and samples. Contact us today to experience the advantages of our products in your manufacturing processes.