Servo motors for precision timing in synchronized systems

Introduction

Servo motors play a crucial role in synchronized systems, providing precise timing and accurate control. In this article, we will explore the various applications and benefits of servo motors in different industries.

1. Understanding Servo Motors

Servo motors are high-performance devices used in automation systems to achieve precise control of motion. These motors are designed to provide accurate position, speed, and torque control, making them ideal for applications that require synchronized movements.

2. The Working Principle of Servo Motors

Servo motors operate on a closed-loop feedback system, which continuously monitors and adjusts the motor’s position to maintain accuracy. This feedback enables the motor to respond to changes in the system, ensuring precise and synchronized movements.

3. Advantages of Servo Motors

Servo motors offer several advantages over other types of motors:

- High precision and accuracy

- Fast response time

- Wide speed range

- Excellent torque control

- Low maintenance

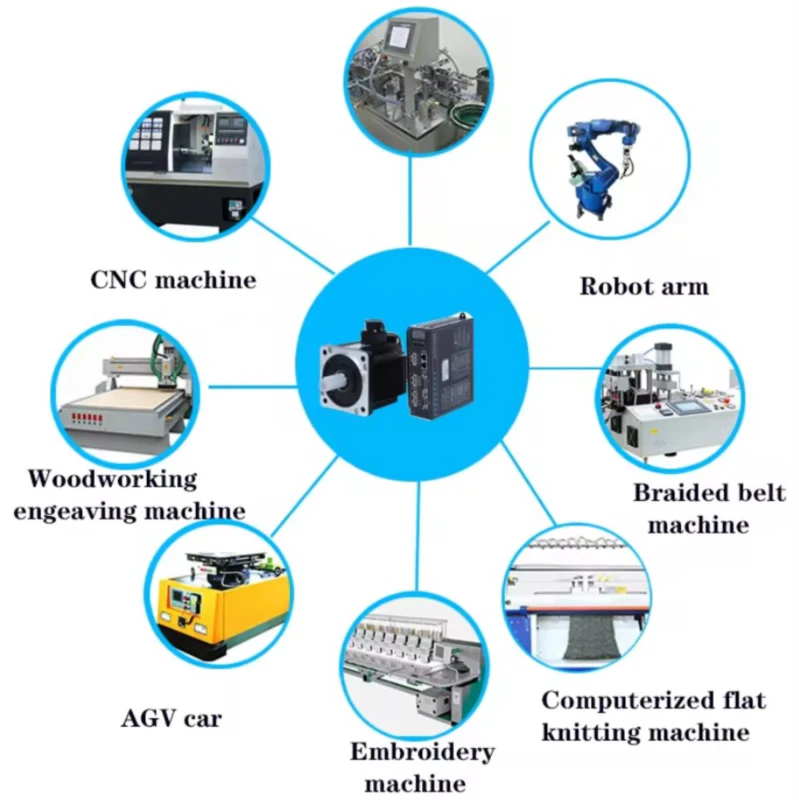

4. Applications of Servo Motors

Servo motors find applications in various industries, including:

- Robotics and automation

- CNC machining

- Printing and packaging

- Textile machinery

- Medical equipment

5. Servo Motors in Robotics and Automation

In robotics and automation, servo motors are used to control the movement of robot arms, grippers, and other mechanical components. The precise control offered by servo motors ensures accurate positioning and smooth operation of robots in manufacturing processes.

6. Servo Motors in CNC Machining

In CNC machining, servo motors are used to control the movement of machine tool axes, enabling precise and intricate cuts. The high speed and accuracy of servo motors contribute to improved productivity and superior surface finish in CNC machining operations.

7. Servo Motors in Printing and Packaging

Servo motors are widely used in printing and packaging machines to control the feeding, cutting, and stacking of materials. The precise control of servo motors ensures consistent and high-quality output, reducing material waste and increasing production efficiency.

8. Servo Motors in Textile Machinery

In textile machinery, servo motors are employed to control the tension, speed, and positioning of yarns and fabrics. This precise control allows for the production of high-quality textiles with minimal defects and variations in pattern and color.

9. Servo Motors in Medical Equipment

Servo motors are critical components in medical equipment such as surgical robots, imaging devices, and rehabilitation equipment. The accurate and smooth motion provided by servo motors ensures safe and precise operation, enhancing the effectiveness of medical procedures.

10. Conclusion

Servo motors are essential for achieving precision timing and synchronized movements in various industrial applications. Their high performance, accuracy, and versatility make them indispensable for industries that require precise control of motion. Embracing servo motor technology can significantly enhance productivity, efficiency, and product quality.

Using Servo Motors in Different Scenarios

Q&A:

Q: What are the advantages of using servo motors in industrial automation?

A: Servo motors offer high precision and accuracy, fast response time, wide speed range, excellent torque control, and low maintenance. These advantages make them ideal for achieving precise control of motion in industrial automation.

Q: Can servo motors be used in outdoor applications?

A: Yes, servo motors can be designed to withstand harsh environmental conditions and can be used in outdoor applications such as agricultural machinery, construction equipment, and surveillance systems.

Q: How can servo motors contribute to energy efficiency?

A: Servo motors are energy-efficient due to their ability to operate at variable speeds and adjust power consumption based on the load requirements. This energy-saving feature makes them an eco-friendly choice for various applications.

About Our Company

Our company is a leading player in the Chinese motor market, specializing in the design and production of servo motors, brake motors, hydraulic motors, Bauer gear motors, hydraulic pistons, and driveline motors. With a production capacity of 200,000 sets, we boast state-of-the-art automatic CNC production and assembly equipment. We take pride in providing high-quality products, competitive prices, and excellent customer service. We welcome customers to contact us for customization based on their drawings and samples.