Servo Motors for Precise Paper Handling

Introduction

In the world of paper handling, precision is key. Servo motors have revolutionized the industry, providing unparalleled accuracy and control. In this blog post, we will explore the various applications of servo motors in paper handling and discuss their benefits.

1. Advancements in Servo Motor Technology

Servo motors have come a long way in recent years, thanks to advancements in technology. These motors are now equipped with high-resolution encoders and advanced control algorithms, allowing for precise positioning and movement control. This level of accuracy is crucial in paper handling applications where even the slightest misalignment can cause major issues.

2. Servo Motors in Paper Feeding Systems

One common application of servo motors is in paper feeding systems. These motors drive the rollers that feed the paper through the machine, ensuring smooth and consistent movement. With their precise control, servo motors can handle various paper sizes and weights, eliminating the need for manual adjustments and reducing the risk of jams or misfeeds.

3. Servo Motors in Print Registration

Print registration is a critical aspect of paper handling, especially in the printing industry. Servo motors play a crucial role in maintaining the alignment of multiple colors or images during the printing process. With their high-speed and accuracy, these motors can make real-time adjustments to ensure perfect registration, resulting in high-quality prints.

4. Servo Motors in Folding and Cutting

Folding and cutting paper requires precise control to achieve accurate results. Servo motors provide the necessary power and precision for these operations. By controlling the position and speed of the folding or cutting mechanism, these motors ensure clean and precise folds or cuts, even at high speeds.

5. Servo Motors in Packaging

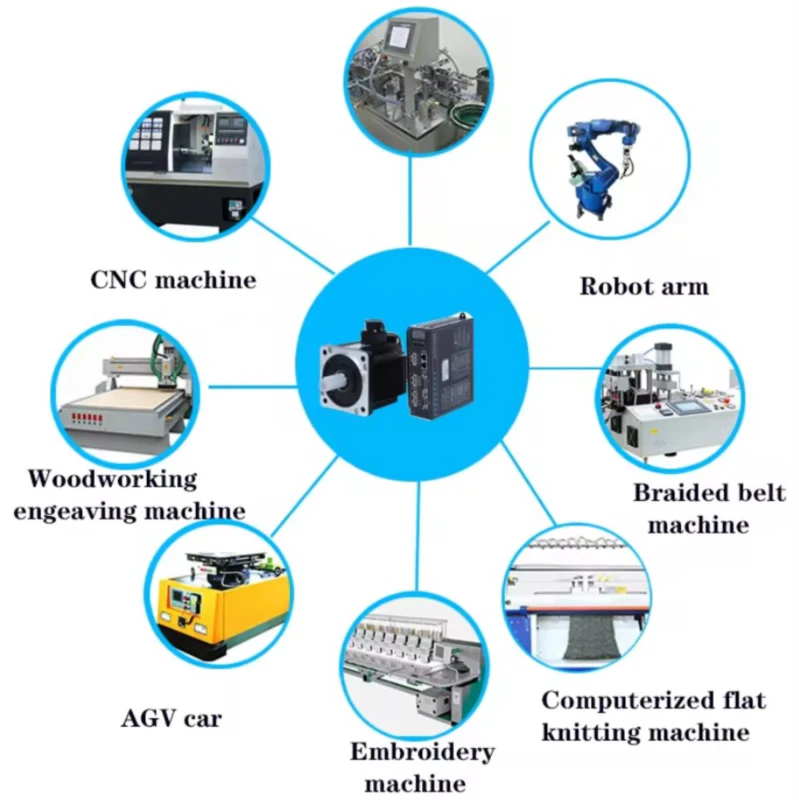

In the packaging industry, servo motors are used to control the movement of conveyors, robotic arms, and other equipment involved in the packaging process. These motors enable precise positioning and synchronization, allowing for efficient and error-free packaging. From filling and sealing to labeling and palletizing, servo motors play a vital role in ensuring smooth operations.

6. Servo Motors for Energy Efficiency

Aside from their precise control capabilities, servo motors are also known for their energy efficiency. Unlike traditional motors, servo motors only consume energy when necessary, reducing overall power consumption and operating costs. This makes them an environmentally friendly choice for paper handling applications.

Conclusion

Servo motors have transformed the paper handling industry with their unmatched precision and control. From paper feeding and print registration to folding and packaging, these motors have revolutionized the way paper is handled. With their advancements in technology, servo motors continue to drive innovation in the field, ensuring efficient operations and high-quality output.

Product Q&A

Q: What are the main advantages of using servo motors in paper handling?

A: Servo motors provide precise control and positioning, reducing the risk of misfeeds, jams, and alignment issues. They also offer energy efficiency, resulting in cost savings and environmental benefits.

Q: Can servo motors handle different paper sizes and weights?

A: Yes, servo motors are highly versatile and can handle various paper sizes and weights. Their advanced control algorithms allow for real-time adjustments, ensuring smooth and consistent paper handling.

Q: How do servo motors contribute to the quality of printed output?

A: Servo motors play a crucial role in print registration, maintaining precise alignment during the printing process. This results in high-quality prints with accurate color registration and sharp details.

Company Promotion

Our company holds a leading position in the Chinese motor market, offering a wide range of products including servo motors, brake motors, hydraulic motors, Bauer gear motors, and more. With a design and production capacity of 200,000 sets, we pride ourselves on delivering high-quality products at competitive prices. Our fully automated CNC production and assembly equipment ensure exceptional precision and reliability. We welcome customers to customize their orders based on drawings and samples.