Servo Motors for Automated Vehicle Systems

Introduction

In the rapidly advancing field of automated vehicle systems, servo motors play a crucial role in ensuring precise control and efficient operation. These high-performance motors are designed to provide accurate and reliable motion control in a wide range of applications. From autonomous cars to unmanned aerial vehicles, servo motors have become an integral part of modern automated systems.

1. Understanding Servo Motors

Servo motors are compact electric motors that are specifically designed for applications requiring controlled motion. They consist of a motor, a feedback device, and a control system. The feedback device continuously monitors the position, speed, and torque of the motor and provides feedback to the control system, allowing it to make real-time adjustments and maintain precise control over the motor’s operation.

2. Advantages of Servo Motors in Automated Vehicle Systems

2.1 High Precision Control

With their advanced control systems and feedback mechanisms, servo motors offer exceptionally precise control over motion. This level of precision is essential in automated vehicle systems, where even the slightest error can have significant consequences. Servo motors ensure accurate positioning, speed control, and torque output, resulting in smooth and efficient operation.

2.2 Fast Response Time

Servo motors are renowned for their quick response time. They can rapidly adjust their position, speed, and torque in real-time, allowing them to keep up with the dynamic nature of automated vehicle systems. Whether it’s sudden changes in direction or unexpected obstacles, servo motors react swiftly, ensuring safe and reliable operation.

2.3 Wide Range of Applications

From steering and braking systems to throttle control and suspension adjustment, servo motors find extensive use in various components of automated vehicle systems. Their versatility and adaptability make them suitable for a diverse range of applications, enabling precise control and enhancing overall system performance.

3. Implementing Servo Motors in Automated Vehicle Systems

3.1 Servo Motors for Steering

One of the critical applications of servo motors in automated vehicle systems is steering control. By utilizing servo motors, vehicles can achieve precise and responsive steering, ensuring optimal maneuverability and safety. The servo motors work in conjunction with sensors and control algorithms to provide accurate and smooth steering control.

3.2 Servo Motors for Throttle Control

In automated vehicle systems, servo motors are also employed for throttle control. These motors enable precise control over the vehicle’s speed, allowing for smooth and efficient acceleration. By adjusting the throttle position in real-time, servo motors contribute to better fuel efficiency and improved driving performance.

3.3 Servo Motors for Brake Systems

The importance of reliable braking systems in automated vehicles cannot be overstated. Servo motors play a vital role in ensuring precise and responsive braking. By controlling the brake force and modulation, these motors enhance the vehicle’s braking performance, providing a safe and comfortable driving experience.

4. Servo Motors in Action

To visualize the application of servo motors in automated vehicle systems, consider the scenario depicted below:

Imagine a self-driving car navigating through a busy city street. The servo motors integrated into the vehicle’s steering system ensure precise control, allowing it to follow the intended path accurately. Simultaneously, servo motors in the throttle and brake systems maintain the desired speed and respond to changing traffic conditions, ensuring a safe and smooth journey.

5. Q&A

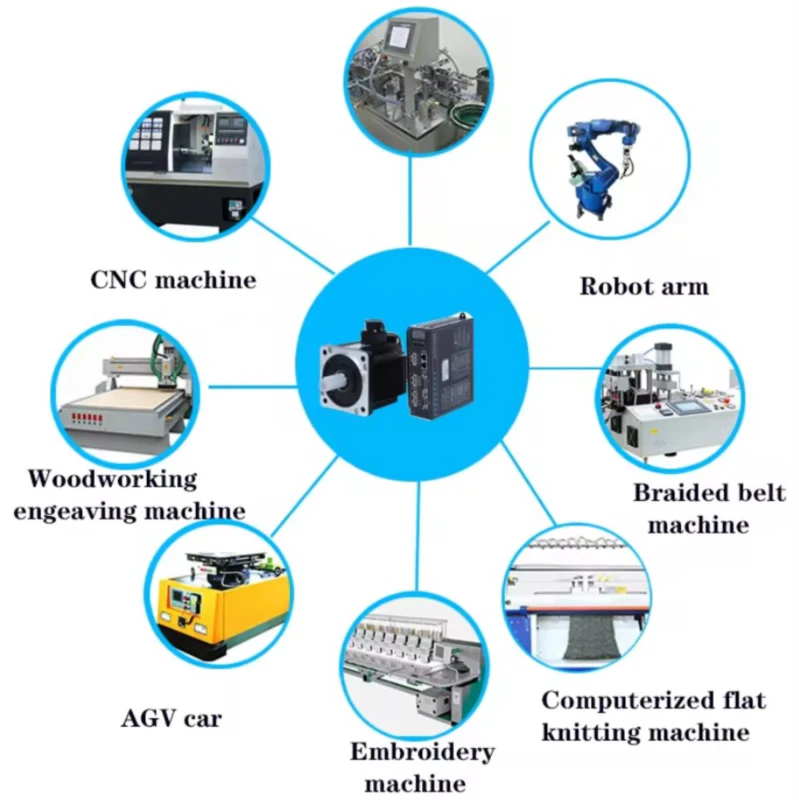

Q1: Can servo motors be used in other industrial applications besides automated vehicle systems?

A1: Absolutely! Servo motors are widely utilized in various industrial applications such as robotics, CNC machines, printing presses, and more. Their precision and versatility make them ideal for any application that requires accurate motion control.

Q2: What are the key factors to consider when selecting servo motors for automated vehicle systems?

A2: When choosing servo motors for automated vehicle systems, factors such as torque output, response time, power efficiency, and environmental durability should be taken into account. Additionally, compatibility with control systems and integration capabilities are crucial for seamless operation.

Q3: Are there any maintenance requirements for servo motors in automated vehicle systems?

A3: Like any mechanical component, servo motors require regular maintenance to ensure optimal performance and longevity. Periodic inspections, lubrication, and monitoring of feedback devices are essential to detect and address any potential issues promptly.

About Our Company

We are a leading company in the Chinese motor market, specializing in the production of high-quality servo motors, brake motors, hydraulic motors, Bauer gear motors, hydraulic pistons, servo motors, driveline motors, and more. With a design and production capacity of 200,000 sets, we are equipped with state-of-the-art CNC production and assembly equipment, ensuring the highest standards of quality and precision. Our products are known for their reliability, competitive prices, and excellent customer service. We welcome customers to customize their requirements based on our drawings and samples.