Servo Motor Calibration for Better Accuracy

Introduction

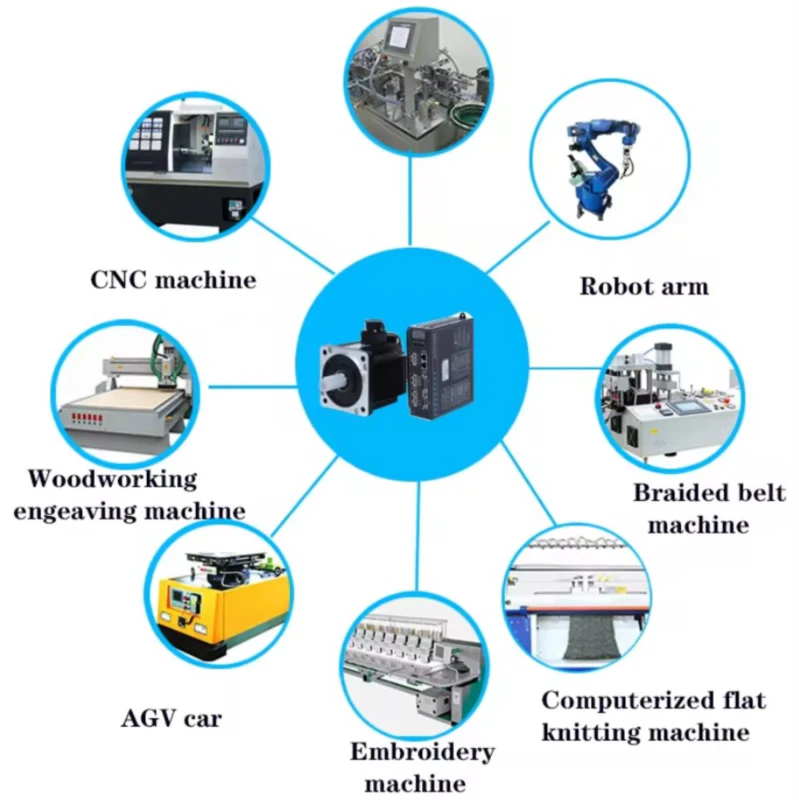

When it comes to precision and accuracy in motor control, servo motors play a crucial role. Servo motors are widely used in various industries, including robotics, automation, and manufacturing. However, to ensure optimal performance, it is essential to calibrate servo motors properly.

Why Servo Motor Calibration is Important

Servo motor calibration is the process of adjusting the motor’s parameters to achieve better accuracy and performance. It involves fine-tuning various factors such as position control, velocity control, and torque control. Proper calibration ensures that the motor responds accurately to input commands, resulting in precise movement and positioning.

The Calibration Process

The calibration process involves several steps:

Step 1: Understanding Motor Specifications

Before starting the calibration process, it is crucial to have a thorough understanding of the servo motor’s specifications. This includes parameters such as rated torque, maximum speed, and resolution. By knowing these specifications, you can set the calibration parameters accordingly.

Step 2: Adjusting Position Control

Position control is one of the key factors in servo motor calibration. It involves setting the motor’s response to position commands accurately. By adjusting the position control parameters, such as proportional gain, integral gain, and derivative gain, you can achieve better positioning accuracy.

Step 3: Fine-tuning Velocity Control

Velocity control is another critical aspect of servo motor calibration. It ensures that the motor maintains a consistent speed during operation. By adjusting the velocity control parameters, such as feedforward gain and speed limit, you can achieve smoother and more precise velocity control.

Step 4: Optimizing Torque Control

Proper torque control is essential for servo motors, especially in applications where high torque is required. By fine-tuning the torque control parameters, such as torque limit and torque response, you can ensure that the motor delivers the required torque accurately and efficiently.

Frequently Asked Questions

Q: Why is servo motor calibration necessary?

A: Servo motor calibration is necessary to achieve better accuracy and performance in motor control applications. It ensures that the motor responds accurately to input commands, resulting in precise movement and positioning.

Q: What are the key parameters to adjust during servo motor calibration?

A: The key parameters to adjust during servo motor calibration include position control parameters, velocity control parameters, and torque control parameters. These parameters determine the motor’s response to different commands and play a crucial role in achieving better accuracy.

Q: How often should servo motors be calibrated?

A: The frequency of servo motor calibration depends on various factors, such as the application and the motor’s usage. In general, it is recommended to calibrate servo motors periodically, especially if there are any noticeable changes in performance or accuracy.

Company Promotion and Introduction

Our company is a leading player in the Chinese motor market, specializing in the design and production of servo motors, brake motors, hydraulic motors, Bauer gear motor, hydraulic piston, driveline motors, and more. With a production capacity of 200,000 sets, we pride ourselves on delivering high-quality products, competitive prices, and excellent customer service. We welcome customers to customize their requirements based on drawings and samples.