Longevity and Durability of Servo Motors

Introduction

In the world of industrial automation, servo motors play a vital role in ensuring precise and controlled movements. With their exceptional performance and reliability, servo motors have become a preferred choice for various industries. In this article, we will explore the longevity and durability of servo motors, shedding light on their key features, applications, and benefits.

1. Understanding Servo Motors

Servo motors are highly advanced electric motors that provide accurate control over angular or linear position, velocity, and acceleration. They utilize feedback mechanisms to constantly monitor and adjust their motion, resulting in precise and consistent performance.

2. Key Features of Servo Motors

Servo motors possess several key features that contribute to their longevity and durability:

- High Torque: Servo motors are designed to deliver high torque even at low speeds, ensuring efficient operation in various applications.

- Compact Size: These motors are compact in size, making them ideal for installations with space constraints.

- Precision Control: Servo motors offer unparalleled precision control, allowing for accurate positioning and smooth movements.

- Quick Response: With their rapid response time, servo motors can quickly adapt to changes in input signals, ensuring optimal performance.

- Low Maintenance: Thanks to their robust construction and quality components, servo motors require minimal maintenance, reducing downtime and costs.

3. Applications of Servo Motors

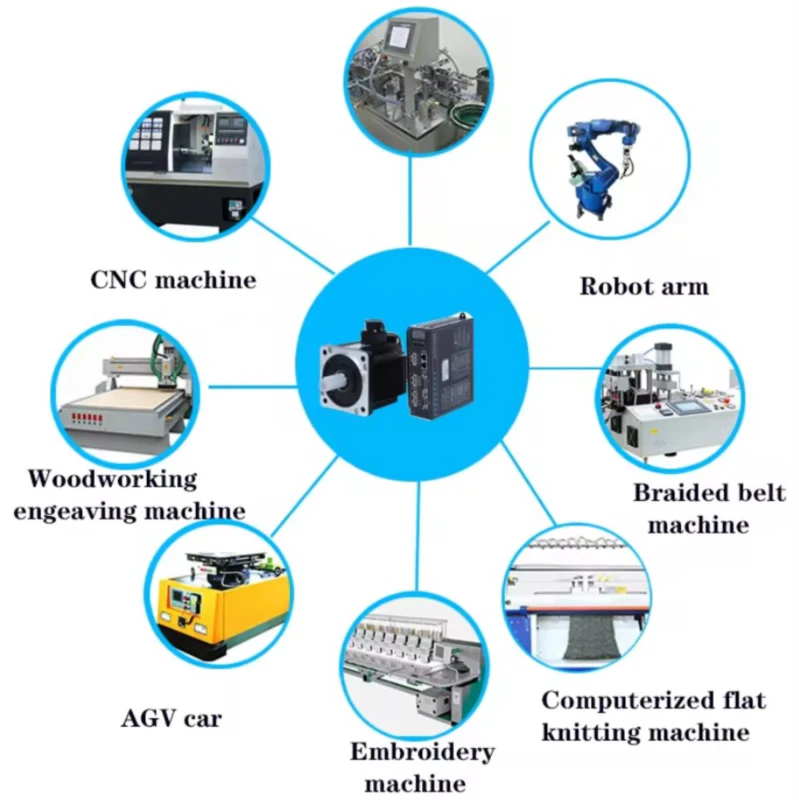

Servo motors find extensive use in various industries due to their exceptional performance and durability:

- Industrial Automation: Servo motors are widely employed in robotics, CNC machines, and other automated systems for precise control and motion.

- Manufacturing: They are utilized in conveyor systems, packaging machines, and assembly lines to ensure accurate movements and high productivity.

- Medical Devices: Servo motors play a critical role in medical devices such as surgical robots and diagnostic equipment, where precision and reliability are paramount.

- Aerospace: These motors are used in aerospace applications for aircraft control surfaces, landing gear mechanisms, and satellite positioning systems.

4. Benefits of Servo Motors

The longevity and durability of servo motors provide numerous benefits:

- Improved Efficiency: Servo motors optimize energy consumption and reduce wastage, leading to enhanced operational efficiency.

- Enhanced Productivity: The precise control offered by servo motors results in increased productivity and improved product quality.

- Cost Savings: With their low maintenance requirements and long lifespan, servo motors help reduce maintenance and replacement costs.

- Greater Flexibility: Servo motors can be easily programmed and adjusted to accommodate different production requirements and operational needs.

Q&A

Q1: How long can servo motors typically last?

A1: The longevity of servo motors depends on several factors, including operating conditions, maintenance practices, and the quality of the motor itself. However, with proper care and regular maintenance, servo motors can generally last for several years, even in demanding industrial environments.

Q2: Can servo motors withstand harsh operating conditions?

A2: Yes, servo motors are designed to withstand harsh operating conditions, including high temperatures, vibrations, and heavy loads. Their robust construction and quality components ensure reliable performance even in challenging environments.

Q3: Can servo motors be repaired if they fail?

A3: In most cases, servo motors can be repaired if they experience a failure. However, it is recommended to consult a professional technician or the manufacturer for proper diagnosis and repair procedures. In some cases, it may be more cost-effective to replace the motor.

Conclusion

As discussed, servo motors offer exceptional longevity and durability, making them a reliable choice for various industrial applications. Their advanced features, precise control, and ability to withstand demanding conditions make them indispensable in the world of automation. Our company, a leader in the Chinese motor market, specializes in the design and production of high-quality servo motors, brake motors, hydraulic motors, Bauer gear motors, hydraulic pistons, and driveline motors. With a production capacity of 200,000 sets, we pride ourselves on offering products of superior quality, competitive prices, and excellent service. We welcome customers to customize their requirements based on drawings and samples.

Finally, take a glimpse into our state-of-the-art manufacturing facility: