Impact of Servo Motors on Precision in Metrology Equipment

Introduction

Servo motors play a crucial role in the field of metrology equipment, where precision is of utmost importance. These motors are highly efficient and provide accurate control over positioning, speed, and torque, which directly impacts the overall precision of the measuring instruments.

Understanding Servo Motors

Before delving into the impact of servo motors on precision in metrology equipment, it is essential to comprehend the working principles of these motors. Servo motors are specially designed electric motors that utilize feedback mechanisms to achieve precise control. They consist of a motor, position sensor, and control circuitry that work together to maintain accuracy and precision in various applications.

Enhancing Precision in Metrology Equipment

1. Sub-micron Accuracy

Servo motors are capable of providing sub-micron accuracy, ensuring that the measuring equipment can detect even the smallest deviations. This level of precision is crucial in industries such as semiconductor manufacturing, aerospace, and medical devices, where accuracy is paramount.

2. Dynamic Response

The dynamic response of servo motors enables rapid adjustments, allowing the metrology equipment to quickly adapt to changes in the measuring environment. This feature ensures that the measurements remain accurate, even when there are external disturbances or variations in the sample being measured.

3. Closed-Loop Control

Servo motors operate in a closed-loop control system, where feedback from the position sensor is continuously monitored and used to make precise adjustments. This closed-loop control mechanism eliminates errors and drift, ensuring that the metrology equipment maintains its accuracy over time.

Applications of Servo Motors in Metrology

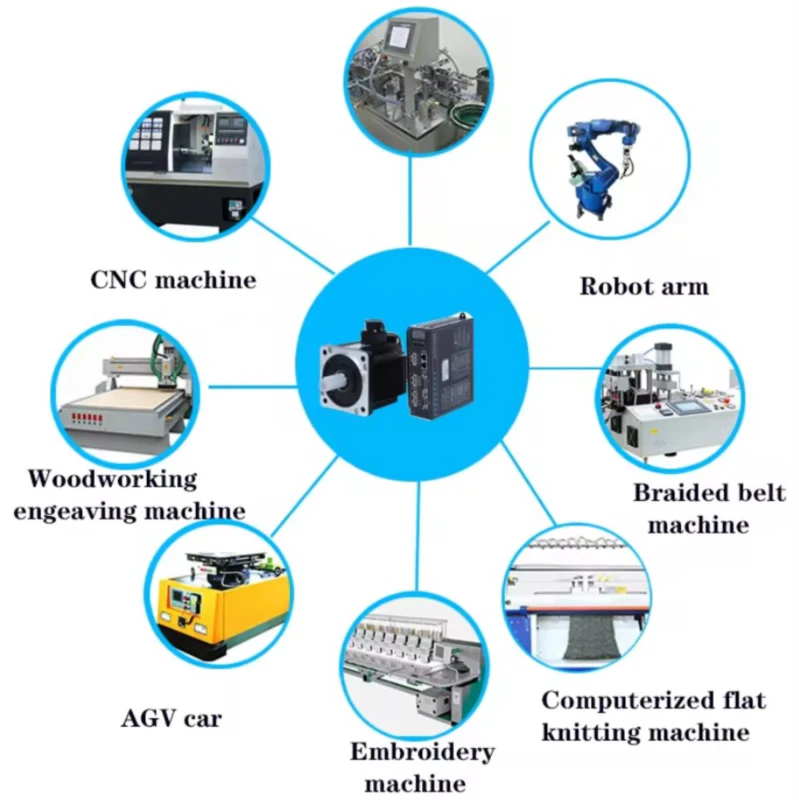

The use of servo motors in metrology equipment is extensive, spanning various industries and applications. Some notable applications include:

1. Coordinate Measuring Machines (CMM): Servo motors are widely used in CMMs to achieve precise and accurate measurements of complex geometries.

2. Optical Measurement Systems: Servo motors play a crucial role in optical measurement systems, enabling high-precision scanning and imaging.

3. Nanometrology: In the field of nanometrology, servo motors are employed to achieve sub-nanometer resolution and precise positioning of probes and manipulators.

Q&A

Q: How do servo motors contribute to the overall accuracy of metrology equipment?

A: Servo motors provide precise control over positioning, speed, and torque, ensuring accurate measurements and minimal errors in the metrology equipment.

Q: Are servo motors suitable for applications requiring rapid adjustments?

A: Yes, servo motors have excellent dynamic response capabilities, allowing quick adaptability to changes in the measuring environment.

Q: Can servo motors maintain their accuracy over time?

A: Yes, servo motors operate in a closed-loop control system and continuously monitor feedback, ensuring long-term accuracy and eliminating errors and drift.

Company Promotion and Introduction

Our company is a leading player in the Chinese motor market, offering a wide range of products including servo motors, brake motors, hydraulic motors, Bauer gear motors, and more. With a design and production capacity of 200,000 sets, we are committed to delivering high-quality products, competitive prices, and excellent service. We welcome customers to customize their requirements based on drawings and samples.