Environmental Benefits of Using Efficient Servo Motors in Manufacturing

Servo motors have become an integral part of modern manufacturing processes due to their efficiency and precision. In this article, we will explore the environmental benefits of using efficient servo motors in manufacturing and how they contribute to sustainable practices.

1. Energy Efficiency

Efficient servo motors are designed to minimize energy consumption by optimizing their power usage. By using advanced control algorithms, these motors operate at high efficiency levels, reducing energy waste and decreasing the overall carbon footprint of manufacturing processes.

2. Reduced Emissions

In traditional manufacturing, inefficient motors contribute to higher emissions of greenhouse gases and pollutants. However, by utilizing efficient servo motors, manufacturers can significantly reduce emissions. These motors produce lower levels of carbon dioxide (CO2) and other harmful pollutants, helping to combat climate change and improve air quality.

3. Waste Reduction

Efficient servo motors enable precise control over machinery, resulting in less material waste. The accurate positioning and speed control provided by these motors minimize product defects and allow manufacturers to optimize production processes. As a result, less raw material is wasted, reducing the environmental impact associated with manufacturing waste.

4. Noise Reduction

Traditional motors often produce excessive noise during operation, leading to a noisy and uncomfortable working environment. In contrast, efficient servo motors operate with reduced noise levels, creating a quieter workplace. This noise reduction not only improves the working conditions for employees but also contributes to a healthier and more pleasant manufacturing environment.

5. Extended Equipment Lifespan

Efficient servo motors are designed to operate at optimal levels, resulting in less stress on machinery. By reducing the strain on equipment, these motors can extend the lifespan of manufacturing machinery. This increased durability decreases the need for frequent replacements, minimizing waste and conserving resources.

In conclusion, the environmental benefits of using efficient servo motors in manufacturing are significant. These motors help conserve energy, reduce emissions, minimize waste, decrease noise pollution, and extend equipment lifespan. By incorporating these motors into manufacturing processes, companies can make substantial contributions towards a sustainable future.

Q&A

Q1: How do efficient servo motors contribute to energy conservation?

A1: Efficient servo motors optimize power usage through advanced control algorithms, resulting in reduced energy consumption and improved energy efficiency in manufacturing processes.

Q2: Can efficient servo motors be retrofitted into existing manufacturing equipment?

A2: Yes, efficient servo motors can often be retrofitted into existing machinery, offering a cost-effective solution for upgrading manufacturing processes and achieving environmental benefits.

Q3: Are there any specific industries that can benefit from using efficient servo motors?

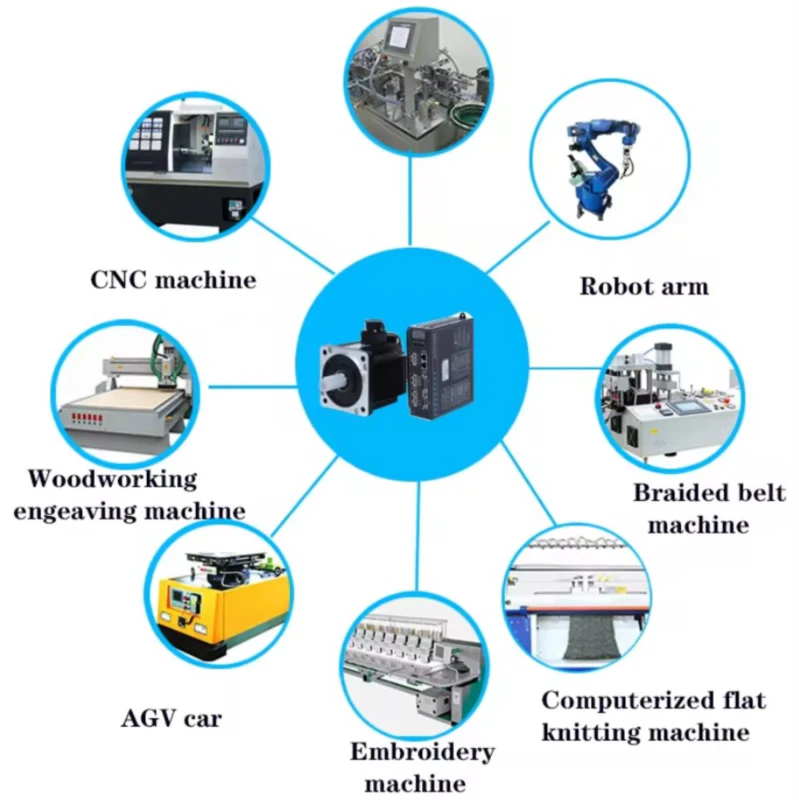

A3: Efficient servo motors can benefit a wide range of industries, including automotive, electronics, packaging, and robotics. Any industry that requires precise control and efficient energy usage can benefit from these motors.

Company Introduction: Our company is a leader in the Chinese motor market, specializing in the production of servo motors, brake motors, hydraulic motors, Bauer gear motor, hydraulic piston, and driveline motors. With a design and production capacity of 200,000 sets, we offer high-quality products at competitive prices. We welcome customers to customize their products based on drawings and samples, and we take pride in providing excellent service.