Energy Efficiency Improvements with Latest Servo Motor Designs

Introduction:

Servo motors, a type of electric motor, are widely used in various industries due to their precise control and high efficiency. With advancements in technology, the latest servo motor designs have brought about significant improvements in energy efficiency, resulting in reduced energy consumption and increased cost savings. In this blog post, we will explore the key features and benefits of these latest servo motor designs.

1. High Torque Density

The latest servo motor designs offer high torque density, which means they can deliver greater power output in a smaller and lighter package. This allows for more compact and efficient machinery design, reducing overall energy consumption and improving performance.

2. Advanced Feedback Systems

To achieve precise control, the latest servo motor designs are equipped with advanced feedback systems, such as encoders and resolvers. These systems provide accurate position and speed feedback, enabling better control over the motor’s operation. This not only improves efficiency but also enhances the overall system performance.

3. Intelligent Power Management

The latest servo motor designs incorporate intelligent power management features, such as energy regeneration and power factor correction. Energy regeneration allows the motor to recover and reuse energy generated during deceleration or braking, reducing overall energy consumption. Power factor correction ensures efficient power utilization and minimizes energy wastage.

4. Efficient Cooling Mechanisms

To prevent overheating and ensure optimal performance, the latest servo motor designs utilize efficient cooling mechanisms, such as liquid cooling or advanced heat sinks. These cooling methods dissipate heat more effectively, allowing the motor to operate at higher power levels without compromising efficiency.

5. Adaptive Control Algorithms

Modern servo motor designs employ adaptive control algorithms that continuously monitor and adjust the motor’s operation based on various factors, such as load conditions and environmental changes. This adaptive control allows for optimal energy usage and improved system responsiveness.

6. Integrated Safety Features

Safety is a crucial aspect in industrial applications. The latest servo motor designs come with integrated safety features, such as overload protection, short circuit protection, and over-temperature protection. These features not only enhance operational safety but also contribute to energy efficiency by preventing motor damage and reducing downtime.

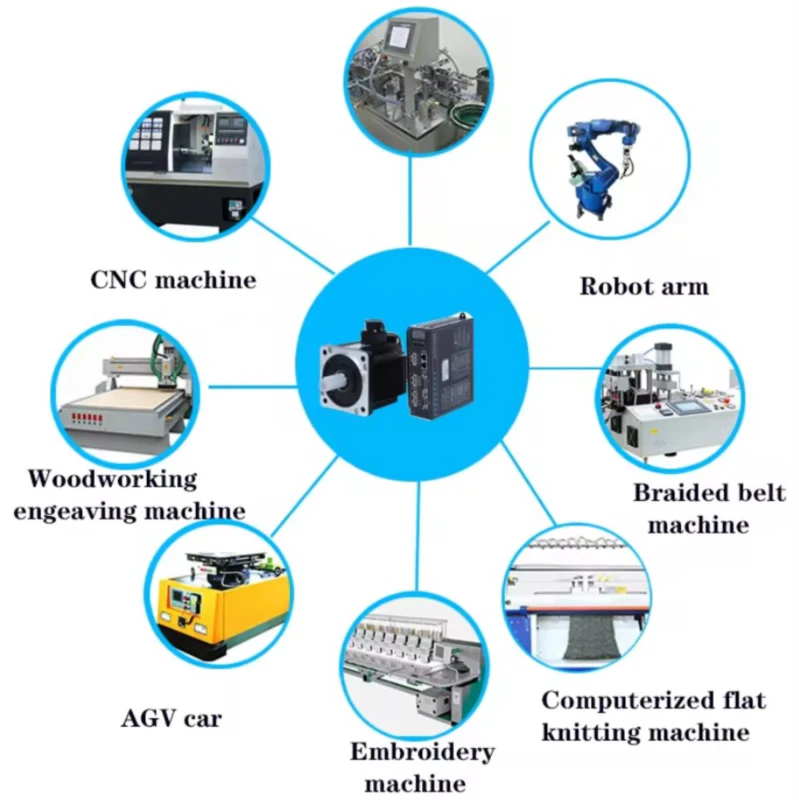

7. Application Examples

The latest servo motor designs find applications in a wide range of industries. One example is in CNC machining, where servo motors provide precise control over cutting tools, resulting in improved accuracy and reduced material wastage. Another example is in robotic systems, where servo motors enable precise movement and positioning, increasing productivity and efficiency.

Q&A:

Q1: How do the latest servo motor designs contribute to energy efficiency?

A1: The latest servo motor designs incorporate features like high torque density, advanced feedback systems, intelligent power management, efficient cooling mechanisms, adaptive control algorithms, and integrated safety features. These features collectively reduce energy consumption and improve overall system efficiency.

Q2: What are the benefits of using servo motors in CNC machining?

A2: Servo motors provide precise control over cutting tools in CNC machining, resulting in improved accuracy and reduced material wastage. This helps to optimize production processes, increase productivity, and reduce operational costs.

Q3: How do servo motors enhance the performance of robotic systems?

A3: Servo motors enable precise movement and positioning in robotic systems, improving overall performance and efficiency. With their high torque density and advanced control capabilities, servo motors enable robots to perform intricate tasks with accuracy and speed.

About Our Company

Our company is a leading player in the Chinese motor market, specializing in the design and production of various motor types. Our product range includes servo motors, brake motors, hydraulic motors, Bauer gear motors, hydraulic pistons, driveline motors, and more. With a production capacity of 200,000 sets, we are equipped with state-of-the-art automatic CNC production and assembly equipment. We pride ourselves on delivering high-quality products, competitive prices, and excellent customer service. We welcome customers to customize their requirements through drawings and samples.