Custom Servo Motor Configurations for Aerospace Component Testing

Introduction

When it comes to aerospace component testing, having the right servo motor configurations is crucial. In this article, we will explore the various custom servo motor configurations that can be utilized for aerospace component testing. These configurations offer precise control, high accuracy, and exceptional performance in demanding testing environments.

1. Understanding the Importance of Custom Servo Motors

Custom servo motors play a vital role in aerospace component testing. With their ability to provide precise positioning and control, they are essential for simulating real-world conditions and evaluating the performance of aerospace components. By customizing servo motor configurations, engineers can optimize testing processes and achieve accurate results.

2. Advanced Features of Custom Servo Motors

Custom servo motors for aerospace component testing come equipped with advanced features that enhance their performance. These features include:

- High torque capabilities for handling heavy loads

- Fast response time for quick adjustments

- High-resolution encoders for precise positioning

- Flexible control options for versatility

- Robust construction for reliable operation in challenging environments

3. Optimizing Servo Motor Configurations for Aerospace Testing

When optimizing servo motor configurations for aerospace testing, several factors need to be considered. These include:

- Load capacity requirements

- Speed and acceleration specifications

- Environmental conditions

- Testing objectives

By carefully analyzing these factors, engineers can design custom servo motor configurations that meet the specific needs of aerospace component testing.

4. Case Study: Custom Servo Motors in Aerospace Component Testing

To illustrate the effectiveness of custom servo motor configurations in aerospace component testing, let’s consider a case study. In this study, a leading aerospace company utilized custom servo motors to simulate extreme flight conditions and evaluate the performance of a critical component.

By leveraging the high torque capabilities and precise control of custom servo motors, the company was able to replicate real-world conditions accurately. The results obtained from the testing process provided valuable insights into the component’s performance and allowed engineers to make necessary improvements.

Q&A

Q1: What are the benefits of using custom servo motor configurations in aerospace component testing?

A1: Custom servo motor configurations offer precise control, high accuracy, and exceptional performance in demanding testing environments. They allow engineers to simulate real-world conditions accurately and evaluate the performance of aerospace components effectively.

Q2: What factors should be considered when optimizing servo motor configurations for aerospace testing?

A2: When optimizing servo motor configurations for aerospace testing, factors such as load capacity requirements, speed and acceleration specifications, environmental conditions, and testing objectives should be carefully analyzed.

Q3: How can custom servo motors improve the testing process in aerospace component evaluation?

A3: Custom servo motors provide high torque capabilities, fast response time, high-resolution encoders, flexible control options, and robust construction. These features enhance the testing process by enabling precise positioning, quick adjustments, and reliable operation in challenging environments.

Company Promotion

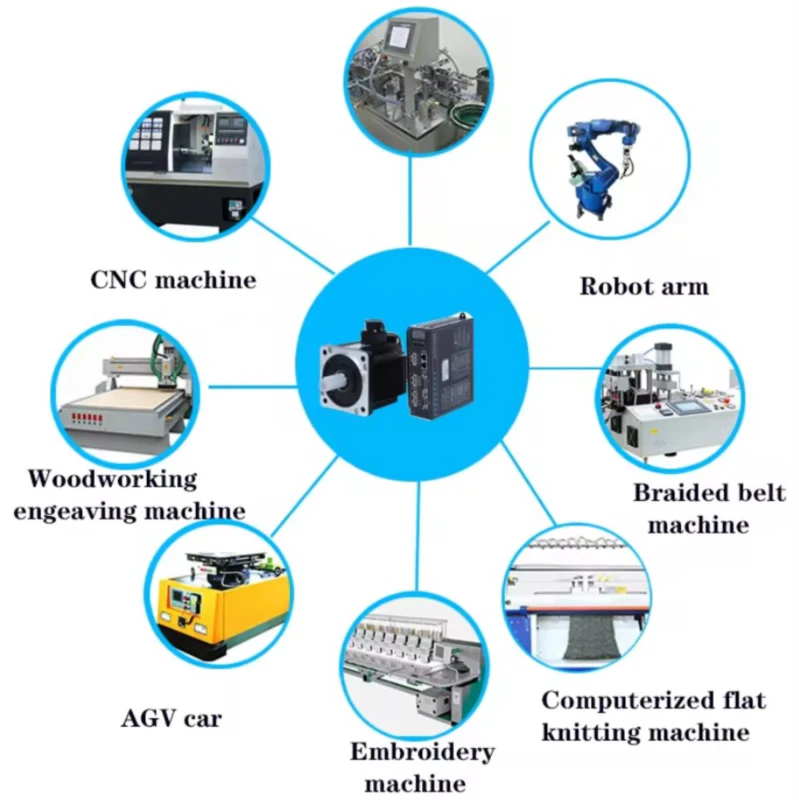

Our company is a leading player in the Chinese motor market, specializing in the production of servo motors, brake motors, hydraulic motors, Bauer gear motors, hydraulic pistons, driveline motors, and more. With a design and production capacity of 200,000 sets, we offer high-quality products, competitive prices, and attentive services. We welcome customers to customize their requirements through drawings and samples.