Advanced Diagnostics and Monitoring for Servo Motor Systems

1. Introduction

Servo motor systems play a crucial role in various industries, providing precise control and high-performance motion. To ensure optimal functionality and prevent unexpected downtime, advanced diagnostics and monitoring techniques have become essential. This article explores the importance of advanced diagnostics and monitoring for servo motor systems, covering various aspects such as predictive maintenance, fault detection, and performance optimization.

2. Predictive Maintenance for Servo Motor Systems

In the realm of servo motor systems, predictive maintenance has gained significant attention. By utilizing advanced sensors and data analysis algorithms, potential issues can be identified before they lead to system failures. Predictive maintenance allows for scheduled maintenance activities, reducing unplanned downtime and improving overall system reliability and productivity.

3. Fault Detection and Diagnosis

Fault detection and diagnosis are critical for servo motor systems, as even minor issues can have significant repercussions on system performance. Through advanced diagnostics, anomalies in motor behavior, such as vibrations or abnormal temperature, can be detected and diagnosed. This not only helps in identifying the root cause of the problem but also enables timely corrective actions to be taken, minimizing the impact on production processes.

4. Performance Optimization Techniques

To achieve optimal performance, servo motor systems require continuous monitoring and fine-tuning. Advanced monitoring techniques, such as real-time feedback control and adaptive algorithms, enable precise adjustments to be made based on changing operating conditions. This ensures that the servo motor system operates at its peak efficiency, resulting in improved productivity and energy savings.

5. Using Advanced Diagnostics and Monitoring in Real-World Applications

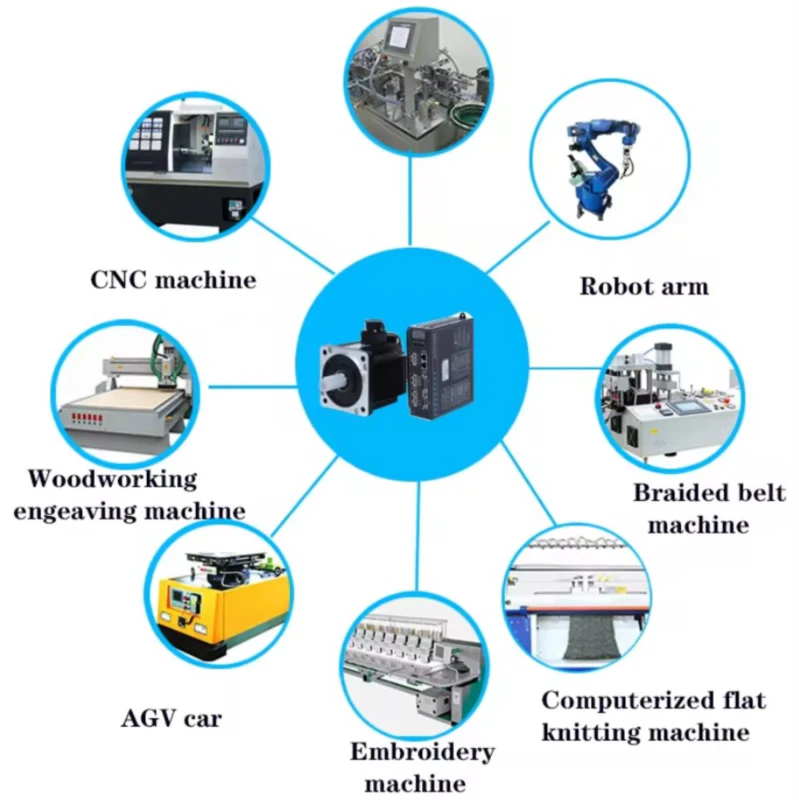

The application of advanced diagnostics and monitoring in servo motor systems is diverse. Industries such as robotics, CNC machining, and automated manufacturing heavily rely on the performance and reliability of servo motor systems. By employing advanced diagnostics and monitoring, these industries can achieve higher levels of operational efficiency, reduced maintenance costs, and increased product quality.

6. Q&A

Q1: How can advanced diagnostics and monitoring improve the lifespan of servo motor systems?

A1: Advanced diagnostics and monitoring allow for early detection of potential issues, enabling proactive maintenance. By addressing problems before they escalate, the lifespan of servo motor systems can be significantly extended.

Q2: Are there any specific challenges in implementing advanced diagnostics and monitoring for servo motor systems?

A2: Yes, implementing advanced diagnostics and monitoring requires specialized expertise in data analysis and system integration. Additionally, the selection and installation of appropriate sensors play a crucial role in ensuring accurate and reliable monitoring.

Q3: How can performance optimization techniques benefit servo motor systems?

A3: Performance optimization techniques, such as real-time feedback control, can enhance the precision and responsiveness of servo motor systems. This leads to improved overall performance, increased productivity, and reduced energy consumption.

For more information about our company and products, please visit our website. We are a leading company in the Chinese motor market, offering a wide range of products including servo motors, brake motors, hydraulic motors, Bauer gear motors, hydraulic pistons, and driveline motors. With a production capacity of 200,000 sets, we are equipped with state-of-the-art automated CNC production and assembly facilities.

We pride ourselves in delivering high-quality products, competitive prices, and excellent customer service. We welcome customers to contact us for customized solutions based on their specific requirements.